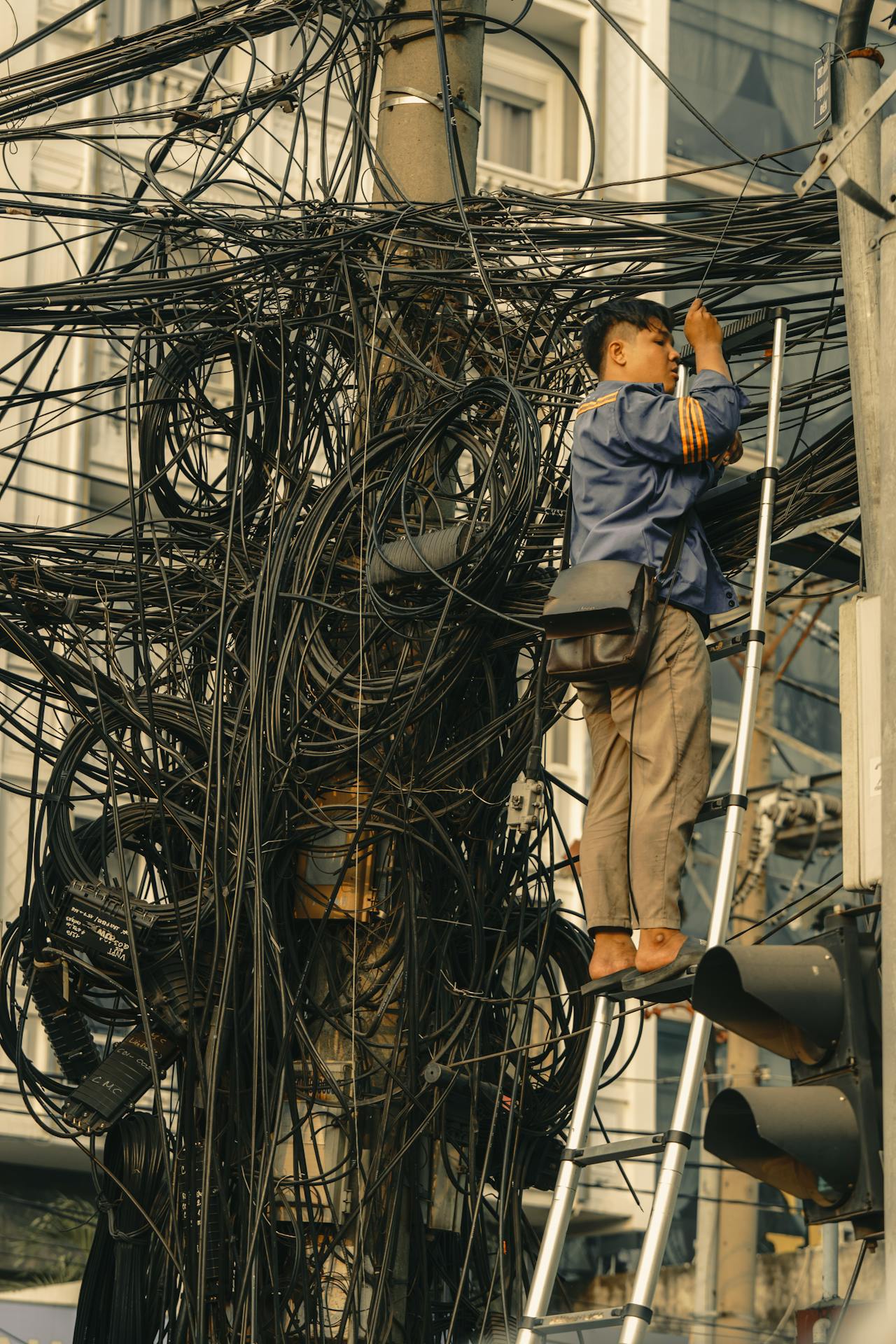

Picture this: you’re overseeing the construction of a new office building in Auckland, perhaps overlooking the harbour. The concrete is poured, the frames are up, and now it’s time to weave the electrical system into the structure. This is no small feat. It requires careful planning, coordination, and a solid understanding of best practices for electrical project management in new builds NZ. Getting it right means a safe, efficient, and reliable electrical system for years to come.

So, what exactly are these best practices? It’s more than just knowing how to run wires. It’s about managing every aspect of the electrical project, from the initial design to the final handover. Let’s dive in and explore how to keep your electrical project on track.

Why Good Project Management Matters: Avoiding the Sparks

When it comes to electrical work, there’s no room for shortcuts or guesswork. Effective project management is crucial for avoiding costly mistakes, delays, and safety hazards. For those working on new builds in New Zealand, particularly in a bustling city like Auckland, proper management can make all the difference. Best practices for electrical project management in new builds NZ ensures:

Safety: Minimises risks and ensures compliance with regulations. This includes adherence to AS/NZS 3000, WorkSafe guidelines, and local council requirements. A strong safety culture, with regular toolbox talks and hazard identification, is vital.

Efficiency: Streamlines the process and reduces wasted time and resources. This involves careful planning, resource allocation, and progress monitoring. Implementing lean construction principles can further enhance efficiency.

Budget Control: Prevents cost overruns and keeps the project on budget. Accurate cost estimation, regular budget reviews, and proactive change management are essential. Contingency planning for unforeseen expenses is also crucial.

Quality Workmanship: Ensures the electrical system is installed to a high standard. Employing skilled and experienced electricians, using quality materials, and conducting thorough inspections are key. Quality assurance measures should be documented and followed.

Timely Completion: Meets project deadlines and avoids delays. Developing a realistic schedule, monitoring progress, and addressing delays promptly are crucial. Effective communication and coordination with other trades are vital to keep the project on schedule.

Key Stages and Best Practices: A Step-by-Step Guide

Best practices for electrical project management in new builds NZ involves careful attention to each stage of the project.

Planning and Design

Detailed Electrical Design: Start with a comprehensive electrical design created by a qualified electrical engineer. This includes load calculations, circuit layouts, and equipment specifications. The design should consider future expansion needs, energy efficiency, and integration with other building systems. It should also be reviewed and approved by all stakeholders.

Early Collaboration: Involve all stakeholders, including architects, builders, and electricians, early in the planning process. This ensures everyone is on the same page and potential issues are identified early. This collaboration should include regular design review meetings and the use of Building Information Modeling (BIM) to visualize and coordinate the electrical system.

Risk Assessment: Conduct a thorough risk assessment to identify potential hazards and develop mitigation strategies. This assessment should cover all aspects of the electrical project, including installation, testing, and commissioning. It should also consider environmental factors and potential impact on other trades.

Budgeting and Scheduling: Create a realistic budget and schedule, taking into account potential delays and unforeseen issues. The budget should include allowances for materials, labor, permits, and contingencies. The schedule should be integrated with the overall construction schedule and regularly updated.

Procurement

Quality Materials: Use high-quality electrical materials that meet New Zealand standards. This includes sourcing materials from reputable suppliers and ensuring they have the appropriate certifications and ratings. Material selection should consider long-term durability and performance.

Reliable Suppliers: Choose reputable suppliers who can deliver materials on time and within budget. Develop strong relationships with suppliers and establish clear communication channels. Regular performance reviews can ensure continued reliability.

Inventory Management: Implement a system for tracking and managing materials to avoid shortages or overstocking. This system should include accurate inventory records, regular stock checks, and a process for ordering and receiving materials. Using a material tracking software will aid in this process.

Installation

Qualified Electricians: Ensure all electrical work is carried out by licensed and registered electricians. Verify the qualifications and experience of all electricians and ensure they are familiar with the project’s design and specifications. Regular safety briefings and training are essential.

Regular Inspections: Conduct regular inspections to ensure the installation is progressing according to the design and specifications. These inspections should be carried out by qualified personnel and documented thoroughly. Any deviations from the design should be addressed promptly.

Site Safety: Implement strict site safety procedures to prevent accidents and injuries. This includes providing appropriate personal protective equipment (PPE), conducting regular safety audits, and enforcing safety regulations. A zero-tolerance policy for safety violations is crucial.

Coordination: Coordinate with other trades to avoid conflicts and delays. This requires clear communication, regular coordination meetings, and the use of scheduling software. Proactive problem-solving and conflict resolution are essential.

Testing and Commissioning

Thorough Testing: Conduct thorough testing of all electrical systems to ensure they are functioning correctly and safely. This includes continuity testing, insulation resistance testing, and RCD testing. Testing should be carried out by qualified personnel using calibrated equipment. Test results should be documented and reviewed by a qualified engineer.

Documentation: Maintain detailed records of all testing and commissioning activities. This documentation should include test reports, calibration certificates, and as-built drawings. It should be stored securely and made available to the building owner or operator.

Handover: Provide clear and comprehensive documentation and training to the building owner or operator. This includes providing operation and maintenance manuals, as-built drawings, and training on the operation of all electrical systems. A handover checklist can ensure that all necessary information is provided.

Communication and Documentation

Regular Meetings: Hold regular meetings with all stakeholders to discuss progress, address issues, and make decisions. These meetings should have a clear agenda and minutes should be recorded and distributed. Regular progress reports should also be provided.

Clear Communication: Maintain clear and open communication channels to ensure everyone is informed. This includes using various communication methods, such as email, phone, and project management software. A communication plan should be developed and implemented.

Detailed Records: Keep detailed records of all project activities, including design documents, installation records, testing results, and meeting minutes. These records should be stored securely and made available to all stakeholders. A document control system can ensure that records are organized and easily accessible.

Auckland’s Specific Considerations: Adapting to the Local Environment

When implementing best practices for electrical project management in new builds NZ, it’s essential to consider Auckland’s unique environment.

Earthquake Resilience: Ensure electrical systems are designed to withstand seismic activity.

Coastal Considerations: If the building is near the coast, use materials that can withstand salt spray.

Local Regulations: Stay up-to-date with Auckland Council’s building codes and regulations.

Choosing the Right Electrical Contractor: A Key Decision

Selecting a qualified and experienced electrical contractor is crucial for the success of your project. Look for a contractor who:

-

Is licensed and registered.

-

Has experience in commercial new builds.

-

Provides detailed quotes and timelines.

-

Has a proven track record of quality workmanship.

-

Understands local regulations and building codes.

Prolectrix has a team of skilled electricians who are well versed in best practices for commercial electrical projects. We can help ensure your new build project is completed safely and efficiently.

Beyond Installation: Ongoing Maintenance and Support

Even after the installation is complete, ongoing maintenance and support are essential for ensuring the long-term reliability of the electrical system.

-

Regular inspections and testing.

-

Prompt repairs and maintenance.

-

Upgrades and retrofits as needed.

Conclusion

Implementing best practices for electrical project management in new builds NZ is essential for ensuring a safe, efficient, and reliable electrical system. By following these guidelines and working with qualified professionals, you can minimise risks, control costs, and achieve project success. Remember, a well-managed electrical project is an investment in the long-term success of your building. It ensures the building is safe, efficient, and able to adapt to future needs. Furthermore, it allows for a seamless transition from construction to occupancy.